Process Development Center

We have lined up process equipment, enlarged clean environment, and various verification and measurement equipment to create new value. We will proactively conduct consortium activities with research and development agencies including materials.

we are challenging the innovation of the manufacturing process,

in order to provide optimal solutions for customers.

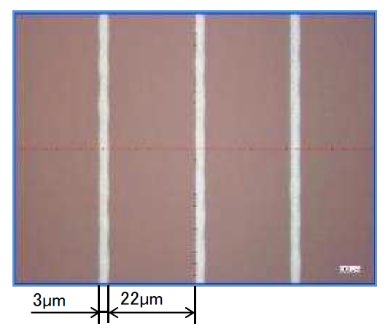

Inkjet Technology

RGB-IJP Equipment

- Fine Dot Printing, 300ppi RGB Printing

RGB-IJP Equipment

| No. | Items | Specifications |

|---|---|---|

| 1 | Substrate size | Max 400×500mm |

| 2 | Method | Piezo Inkjet |

| 3 | Materials |

UV cure resin Conductivity resin Resin with solid content Material with QD |

| 4 | Volume(pl) | 2~4 |

| 5 | Environment | Air・N2 |

TFE-IJP Equipment

- Surface Printing: Thickness 1~200μm

TFE-IJP Equipment

| No. | Items | Specifications |

|---|---|---|

| 1 | Substrate size | Max 370×470mm |

| 2 | Method | Piezo Inkjet |

| 3 | Materials |

UV cure resin Conductivity resin Liquid crystal |

| 4 | Volume(pl) | 6~40 |

| 5 | Environment | Air・N2 |

IJ / Jet Printing Equipment

- Evaluate High viscosity materials by IJP and Jet Dispenser

IJ / Jet Printing Equipment

| No. | Items | Specifications |

|---|---|---|

| 1 | Substrate size | Max 370×470mm |

| 2(1) | Method | Piezo Inkjet |

| Volume(pl) | 2~40 | |

| Viscosity(mPa.s) | 10~500(heated) | |

| 2(2) | Method | Jet |

| Volume(µl) | 0.001~0.2 | |

| Viscosity(mPa.s) | 100~100,000 |

Vacuum Dryer

- The vacuum dryer that can be set vacuum profile and temperature

Vacuum Dryer

| No. | Items | Specifications |

|---|---|---|

| 1 | Substrate size | Max 400×500mm |

| 2 | Evacuation | DP, TMP |

| 3 | Evacuate speed | DP:30,000L/min TMP:1,300L/min |

| 4 | Evacuate control | Configurable |

| 5 | Heat table | Max 250℃ |

| 6 | Degree of vacuum | Below 0.1Pa |

Bake Oven

- Bake oven that can be set temperature

Bake Oven

| No. | Items | Specifications |

|---|---|---|

| 1 | Substrate size | Max 400×500mm |

| 2 | Slot | 2 slot |

| 3 | Heat table | Max 250℃ |

| 4 | Substrate position (height) | Configurable (0~5mm) |

Offline Equipment

- Evaluate for stable volume jetting of material

Offline Equipment

| No. | Items | Specifications |

|---|---|---|

| 1 | Method | Piezo Inkjet |

| 2 | Materials |

UV cure resin Conductivity resin Liquid crystal |

| 3 | Volume(pl) | 6~40 |

| 4 | Environment | Air |

Dispense・Alignment Technology (ODF)

Dispenser

- LCD:Seal/LC dispensing

OLED:DAM/FILL dispensing - Optimize for each materials by various of DSP head and Inkjet head

Dispenser

| No. | Items | Specifications |

|---|---|---|

| 1 | Seal/DAM dispense | Pneumatic Dispenser |

| 2 | Seal/DAM viscosity | 10,000~1,000,000mP・s |

| 3 | LC/FILL dispense 1 | Micro Syringe |

| 4 | LC/FILL viscosity | 10~500mPa・s |

| 5 | LC/FILL dispense 2 | Inkjet |

| 6 | LC/FILL viscosity | 5~15mPa・s |

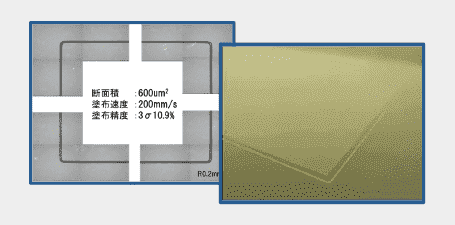

Inkjet Equipment

- Capable of forming nano-level thin films of functional materials

- Inkjet head can be selected according to the customer's purpose

Inkjet Equipment

| No. | Items | Specifications |

|---|---|---|

| 1 | Substrate size | Max 400×500mm |

| 2 | IJP head | 1/3.5/10/14pl etc. |

| 3 | Heat unit | Heat Max 50℃ |

| 4 | Resolution | Minimum 1μm |

| 5 | Speed | Max 200mm/s |

| 6 | LED-UV | 365nm |

| 7 | Materials | Various (Please ask) |

Vacuum Alignment System

- Bonding by ODF method under high vacuum is possible even for large substrates

- Multi-size support is now possible

Vacuum Alignment System

| No. | Items | Specifications |

|---|---|---|

| 1 | Substrate size | Mas 925×1500mm |

| 2 | Chuck method | D-PSC Adhesive Pad |

| 3 | Degree of vacuum | 0.5Pa |

| 4 | Mechamical press | Max 5.0KN |

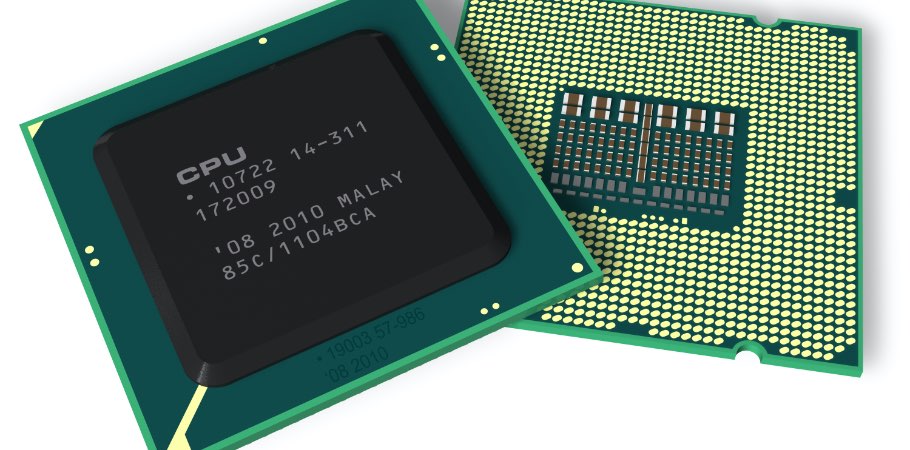

Semiconductor Package Technology

Micro ball Mount System

- Applicable for PCB/Wafer Apply 40um ball mounting

- Realize high throughput by systemize inspection and repair equipment

Micro ball Mount System

| No. | Items | Specifications |

|---|---|---|

| 1 | Substrate | PCB/Wafer |

| 2 | Substrate size | Max 300x300mm*1 |

| 3 | Substrate thickness | 0.10㎜~ |

| 4 | Ball size | 40μm~ |

| 5 | Ball pitch | 85μm~ |

| 6 | Line tact | 60 sec (depends on conditions) |

| 7 | Accuracy | ±10um |

| 8 |

Inspection & Repair Camera resolution |

4.5um Pixel |

| 9 |

Inspection & Repair Repair nozzle |

2 or 4 nozzle |

Vacuum/Air Laminator

- Laminate film on both sides of substrate by roll-to-roll method

- Vacuum bonding can be selected and micro voidless or stepped voidless bonding is possible

Vacuum/Air Laminator

| No. | Items | Specifications |

|---|---|---|

| 1 | Base size | Max 350mm |

| 2 | Film width | Max 330mm |

| 3 | Lamination roll | Jacket roll with induction heat |

| 4 | Speed | 0.1~4.0m/min |

| 5 | Pressure | Max 7N/cm |

| 6 | Temperature | R.T.~150℃±3℃ |

| 7 | Degree of vacuum | 50Pa |

Thin Film Forming Technology

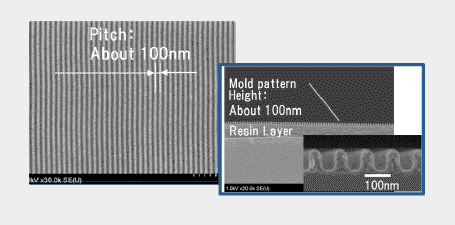

Nanoimprint Equipment

- Film soft mold can be formed from master mold

- Voidless imprint is possible with imprint roll and soft mold

Nanoimprint Equipment

| No. | Items | Specifications |

|---|---|---|

| 1 | Substrate size | Max 300×400mm |

| 2 | Film width | Max 300mm |

| 3 | Imprint pressure | Max 1000N |

| 4 | Imprint speed | 0.1~100mm/s |

| 5 | Demolding speed | 0.1~100mm/s |

| 6 | LED-UV | 365nm Scan type |

| 7 | Materia coating | IJP demo equipment |

Spin Coating Equipment

- Efficient and uniform spin coating of chemicals such as photoresist on the substrate

Spin Coating Equipment

| No. | Items | Specifications |

|---|---|---|

| 1 | Model number | K-359SD-2 |

| 2 | Substrate size | Max φ8 inch (200mm) |

| 3 | Forming thickness | 10nm~several um |

| 4 | Rotation | Max 7,000rpm |

| 5 | Rotation accuracy | ±0.2%(~3,000rpm) |

| 6 | Fix method | Vacuum suction |

| 7 | Materials | Drop by Demo equipment |

Spatter Equipment

- Capable of forming metal films such as AL and Cr at the nano level

Spatter Equipment

| No. | Items | Specifications |

|---|---|---|

| 1 | Model number | SH-450-T10 |

| 2 | Substrate size | Max φ8 inch (200mm) |

| 3 | Power source |

2kW High Frequency Power Source x 1 set Possible to form insulation material and Metal target |

| 4 | Reversed spatter | Yes |

| 5 | Spatter cathode | φ6 inch Nonmagnetic Cathode x 3 sets |

| 6 | Process gas | Ar、N2 |

| 7 | Degree of vacuum | Below 1.0×10-4Pa |

ICP Etching Equipment

- Possible to etch for Sub-micron pattern

- Possible to etch and ash in the same chamber

ICP Etching EquipmentによるSiエッチング例

| No. | Items | Specifications |

|---|---|---|

| 1 | Model number | SERIO-2A-LHOF |

| 2 | Substrate size | Max φ8 inch (200mm) |

| 3 | Power |

2kW High Frequency Power Source x 1 set 500W Low Frequency Power Source x 1 set |

| 4 | Work fix method | Static chucking method (with cooling mechanism) |

| 5 | Taper angle cotrol | 90°~85° |

| 6 | Process gas | Max 5 system (CL・F gas) |

| 7 | Degree of vacuum | <1.3×10-3Pa(ICP room) |

Measuring Equipment and Others

Surface Reforming Equipment

- Excimer UV method

- Substrate size:

Max □1000mm

Film Thickness Step Measuring Device

- Contact method by needle

- Substrate size:

Max □210mm

Shape Analysis Laser Microscope

- Violet semiconductor laser: 404nm (class 2) non-contact type

- Substrate size:Max □300mm

UV Curing Oven

- Curing material by UV radiation

| No. | Items | Specifications |

|---|---|---|

| 1 | Size | 730×900mm |

| 2 | Method | Metal Halide |

| 3 | Wave Length | 330~450nm |

| 4 | Illumination | 100mW/cm2 |

Ultrasonic Cleaner

- Max□370×470mm size is applied

| No. | Items | Specifications |

|---|---|---|

| 1 | Tank | 2 tank |

| 2 | Cleaning | Shake and Temp control |

| 3 | Solvent | Pure water/Cleaning solvent |

| 4 | Drying | Hot air |

Large size Bake Oven

- Max□1,500×900mm(G6-Half) glass is applied

- Large size oven that can handle various heat treatment such as Dry, Baking and Annealing

| No. | Items | Specifications |

|---|---|---|

| 1 | Model number | HLKS-4C |

| 2 | Substrate size |

Max 1,500×900 mm (3 slots) |

| 3 | Method | Air circulation |

| 4 | Heat temperature | Max 300 ℃ |

| 5 | Environment | Air |