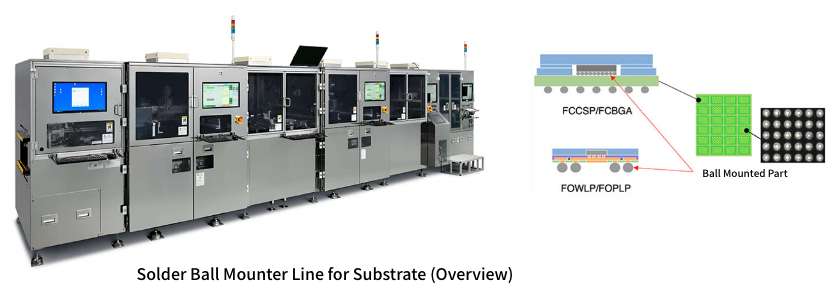

Solder Ball Mounter

(Substrate)

Features

- Solder Ball Mounter for Φ40um Balls to meet the needs of Advanced Semiconductor Packages

- Realized High Throughput by New Rotary Squeegee (25% faster compared with conventional type)

- On-the-Fly Continuous Inspection Function applicable for Llarge-sized Semiconductor Packages for Server such as HPC

Solder Ball Mounter

(Wafer)

Features

- Realized High Yield by applying Ball Mounting Technologies for Semiconductor Package Substrate to Wafer.

- Enabled High Throughput and improved Solder Ball Usage Efficiency with New Inifity Head (1/2 compared with conventional type)

- Enabled to total Solution for Solder Ball Mounter System with Inspection and Repair Equipment

Solder Ball Mounter System for Φ30um

(Flux Application by applying Ink-Jet Printing (IJP) Technologies)

Features

- Realized Uniform Flux Application applicable for Narrower Pitches by applying Ink-Jet Printing (IJP) Technologies

- Contributed to improve Yield and Productivity by New Rotary Head and On-the-Fly High-Speed Inspection & Repair

- Improved Material Usage Efficiency with Maskless (No Conventional Stencil Mask is needed for Flux Printing Process) (Twice as much as Conventional Type)

Plasma Laser Inspection & Repair Equipment

Features

- Realized Inspection and Repair for Solder Ball Drop Defects during Reflow and Flux Cleaning Processes

- Realized Spot Reflow by integrating Plasma and Laser Technologies and minimized Reflow Process

- Enabled to propose In-Line System with Solder Ball Mounter